A jib crane is a type of overhead lifting device that is frequently used in smaller work cell areas for unique and repetitive lifting tasks.

Jib cranes are helpful in production environments because they improve safety, increase worker productivity, and reduce workplace injuries. They are typically easy to operate, and they usually require little maintenance thanks to their relatively simple design.

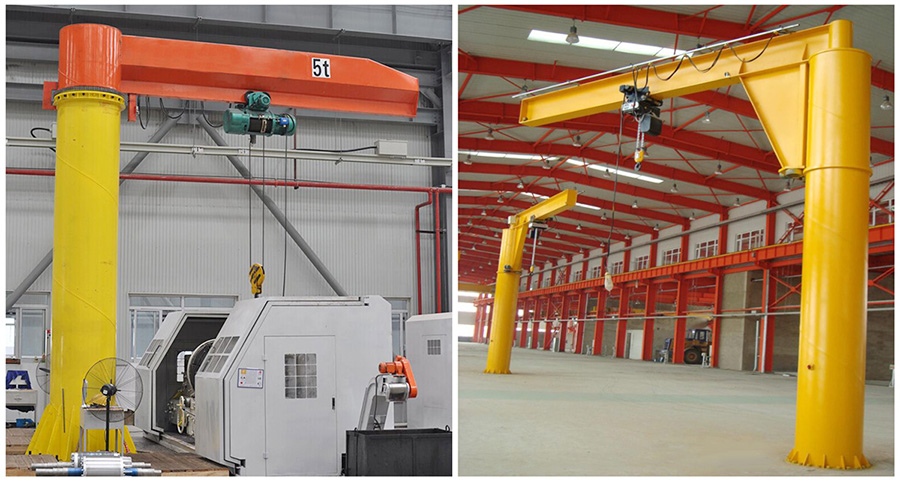

Jib cranes contain several basic design features, which vary between different types of jib cranes; these features are the boom, the mast, and the hoist. The boom is the horizontal beam that extends from the support and holds the load. The mast is the vertical beam or pipe steel that supports the boom and allows the system to rotate. The movable hoist is used to lift, position, and lower a load.

Another component of most jib cranes is the trolley. The trolley can have manual, motorized, or pneumatic motion, carrying the hoist, wire rope or chain, and the hook through the entire length of the boom. The rotation can vary depending on the type of jib crane. Wall-mounted and column-mounted jib cranes offer 180-200 degrees of rotation, and freestanding and mast-style jib cranes can achieve 360 degrees of boom rotation. Additionally, electric or pneumatic power can be added to the mast to provide rotation assistance and allow for a continuous 360-degree boom rotation.

A push-button controller can be used on motorized or air-powered jib systems to control the rotation of the boom, in addition to the motion of the trolley and the lifting and lowering hoist motion. Variable speed controls and multi-speed controls can be used for the hoist and trolley.

Rotation stops limit the crane’s motion before it collides with a nearby object. Rotation stops are crucial if the crane is located close to a wall or other obstruction.

Wall-mounted jib crane systems can be used in individual bays, along structurally adequate walls or building support columns, or as a supplement to an existing monorail or overhead bridge crane. The main advantage of using a wall-mounted system is the space-savings that it offers. They don’t require any type of floor or foundation support, and they can also be installed very close to the underside of the lowest ceiling obstruction, providing maximum clearance both under and above the boom.

These systems can be designed to swing around obstacles, under obstructions, or fold out of the way of overhead cranes to ensure no interruption of production.

Wall or column-mounted jib cranes can accommodate:

Spans ranging from 8-30’

Capacities up to 5 tons

180°-200° rotation

While these types of jib systems are among the most economical in price and design, the major disadvantage of using a wall-mounted or column-mounted jib crane is that the design does not allow for full 360° of rotation. They also require a column or support capable of withstanding the loads, which typically requires a structural engineering survey and approval prior to installation.

Address : No.001,Jingfang Road, Economic & Development Zone, Xinxiang City,Henan Province.China.

Address : No.001,Jingfang Road, Economic & Development Zone, Xinxiang City,Henan Province.China.

Mob :

0086-15137376132

Mob :

0086-15137376132

Tel :

0086-0373-5128206

Tel :

0086-0373-5128206

E-mail :

sales@aidecrane.com

E-mail :

sales@aidecrane.com

Copyright © 2009-2023 All Rights Reserved.

sitemap