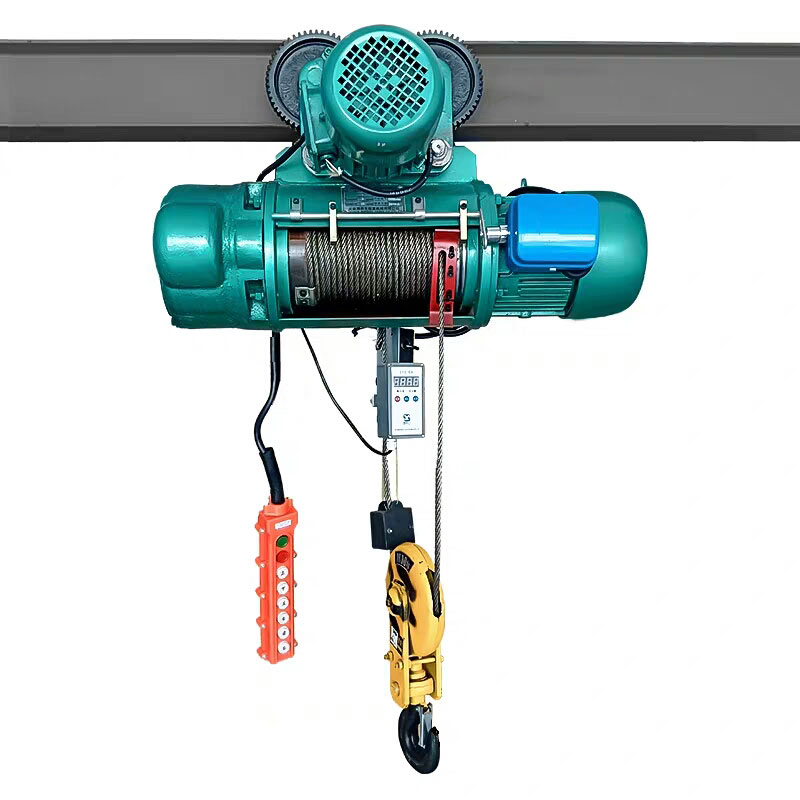

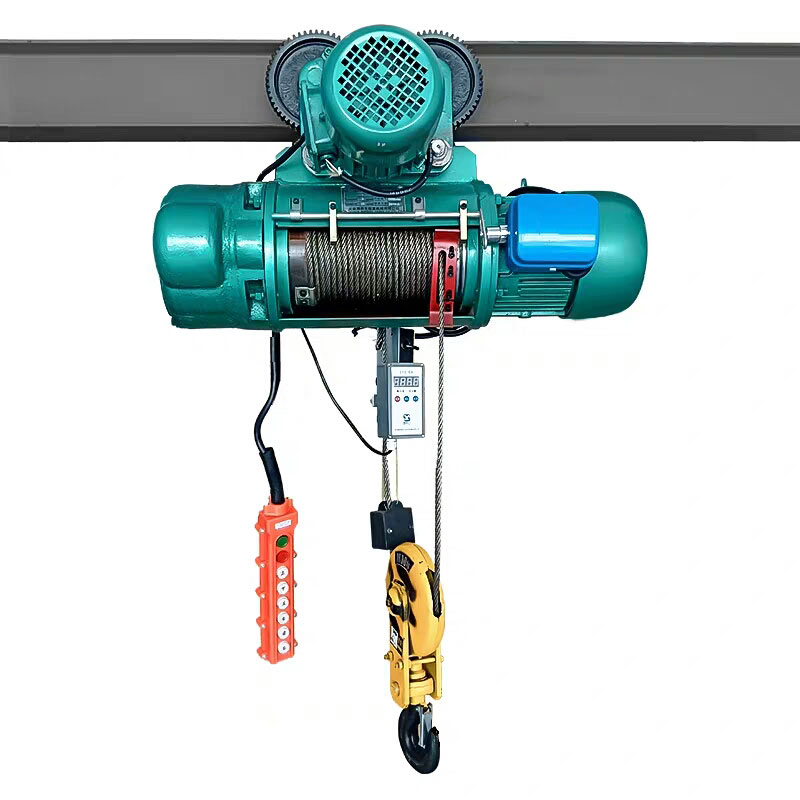

Electric Hoist

Lifting Weight : 0.25-20 (T)

Hoisting Height : 3-30 (m)

Travel Speed : 20/30 (m/min)

Power : 0.4-18.5 (kw)

Electric hoist is a common use lifting equipment installed on overhead cranes and gantry cranes. The electric hoist has the characteristics of small size, light weight, simple operation and convenient use. It is used in industrial and mining enterprises, warehousing, docks and other places.

The electric hoist has a compact structure and uses a worm gear drive with the motor axis perpendicular to the drum axis. Its disadvantages are: large length and width, bulky structure, low mechanical efficiency, and difficult processing. The hydraulic system has dual control. The overflow regulating valve and magnetic contact pressure gauge can accurately control the pressure. The electrical control department adopts low voltage control, which increases the safety of the control system.

This series electric hoist is designed and built to be a nation-standardized light lifting equipment with two models CDH and MDH, its rated work classification is M3. The CDH type has only one lifting speed, the MDH has two instead. Both CDH and MDH hoist features compact body, small size, light weight, and modular convertible parts. Proving to be durable, easy for operation, installation and maintenance, these wire rope models are ideal use for 3 phase, light moderate duty service applications.

Model CDH/MDH options include deck/base mount or lug suspended hoists, top-running or under-slung trolley / hoist configurations. The traveling configurations hoists usually can be installed separately on suspension I-steel runway (straight or curve) or box beam, as well be incorporated into lifting system such as sing/double girder crane, cantilever crane, and gantry crane, and so on.

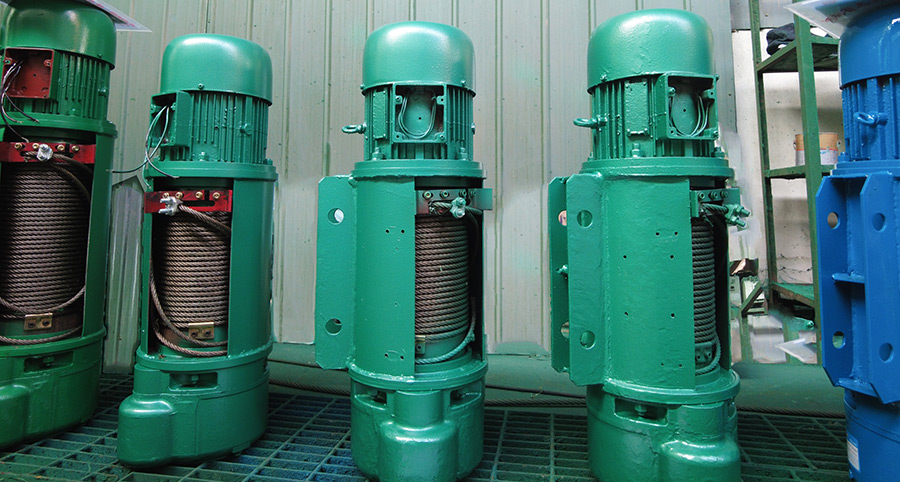

The components of wire rope electric hoist are: motor, transmission mechanism, drum and sprocket. They can be roughly divided into four types based on the different positions of the motor and the drum. The pressed steel wire rope has a strong pulling force, beautiful and fast, and crimping a set of steel wire ropes can be completed in just a few minutes, greatly reducing labor intensity and improving work efficiency.

Electric hoist structure reducer: It adopts a three-stage fixed-axis helical gear rotation mechanism. The gears and gear shafts are made of heat-treated alloy steel. The box body and lid are made of high-quality cast iron, with tight assembly and good sealing. The reducer is a self-contained component and is extremely easy to assemble and disassemble.

Control box: adopts a device that can cut off the main circuit in an emergency and has an upper and lower stroke protection fire limiter. The safe operation of the electric hoist is ensured. The electrical components have long life and are reliable in use.

Steel wire rope: Lifting steel wire ropes include phosphate-coated steel wire ropes, galvanized steel wire ropes and stainless steel wire ropes.

Conical motor: The hoisting motor uses a large starting torque conical rotor to brake the asynchronous motor, without the need for external brakes. The motor load duration is 25%, the motor adopts Class B or F insulation, and the motor protection grade is IP44/IP54.

Button switch: The hand operation is light and flexible, and it can be divided into two modes: corded operation and wireless remote control.

The components of wire rope electric hoist are: motor, transmission mechanism, drum and sprocket. They can be roughly divided into four types based on the different positions of the motor and the drum. The pressed steel wire rope has a strong pulling force, beautiful and fast, and crimping a set of steel wire ropes can be completed in just a few minutes, greatly reducing labor intensity and improving work efficiency.

Product parameters

Model |

CDH/MDH |

|||||||||||||||||||||||||

Capacity |

T | 0.25 |

0.5 |

1 |

2 |

3 |

||||||||||||||||||||

Hoisting Height |

M | 3 | 6 | 9 | 3 | 6 | 9 | 6 | 9 | 12 | 18 | 24 | 30 | 6 | 9 | 12 | 18 | 24 | 30 | 6 | 9 | 12 | 18 | 24 | 30 | |

Lifting speed |

M/min | 8 |

8 |

8 |

8 |

8 |

||||||||||||||||||||

Travel speed |

M/min | 20 |

20 |

20 |

20 |

20 |

||||||||||||||||||||

| Wirerope | Dia | mm | 3.6 |

4.7 |

7.7 |

13 |

13 |

|||||||||||||||||||

Construction |

6x19 |

D-6x37+1 |

D-6x37+1 |

D-6x37+1 |

D-6x37+1 |

|||||||||||||||||||||

| Track | T-steel specification |

16-22b |

16-28b |

16-28b |

20a-32c |

20a-32c |

||||||||||||||||||||

| Min. curvature radius | m | 0.8 |

1.5 |

1.5 |

2 |

3 | 4 | 2 |

2.5 |

3 | 4 | 2 |

2.5 |

3 | 4 | |||||||||||

Power source |

3-phase, AC, 380V,50HZ |

|||||||||||||||||||||||||

Working system and |

Intermediate FC=25%, |

|||||||||||||||||||||||||

| Hoisting motor | Power | Kw | 0.4 |

0.8 |

1.5 |

3 |

4.5 |

|||||||||||||||||||

| Rotation speed | R/min | 1380 |

1380 |

1380 |

1380 |

1380 |

||||||||||||||||||||

| Current | A | 1.25 |

2.4 |

4.3 |

7.6 |

11 |

||||||||||||||||||||

| Travelling motor | Power | Kw | 0.06 |

0.2 |

0.2 |

0.4 |

0.8 |

|||||||||||||||||||

| Rotation speed | R/min | 1400 |

1380 |

1380 |

1380 |

1380 |

||||||||||||||||||||

| Current | A | 0.30 |

0.72 |

0.72 |

1.25 |

1.25 |

||||||||||||||||||||

| Net weight ±15% (kg) |

CD |

44 | 44.4 | 45 | 120 | 125 | 145 | 145 | 158 | 180 | 195 | 208 | 222 | 235 | 248 | 296 | 320 | 340 | 365 | 280 | 300 | 350 | 380 | 405 | 435 | |

MD |

135 | 140 | 160 | 160 | 170 | 200 | 210 | 220 | 230 | 265 | 278 | 326 | 350 | 370 | 395 | 310 | 330 | 380 | 410 | 435 | 465 | |||||

CD fixed |

30 | 30.4 | 31 | 80 | 85 | 90 | 110 | 120 | 125 | 140 | 150 | 165 | 168 | 180 | 190 | 210 | 230 | 350 | 220 | 235 | 250 | 275 | 300 | 325 | ||

MD fixed |

100 | 105 | 110 | 130 | 140 | 145 | 155 | 165 | 180 | 196 | 210 | 220 | 240 | 260 | 280 | 250 | 265 | 280 | 305 | 330 | 355 | |||||

| Main dimension (mm) |

H |

423 |

630 |

670 | 960 |

960 |

985 |

1080 |

||||||||||||||||||

E |

395 |

493 |

584 |

740 |

848 |

|||||||||||||||||||||

L2 |

216 |

126 |

159 |

187 |

230 |

|||||||||||||||||||||

L1 |

274 | 346 | 418 | 345 | 443 | 541 | 737 | 933 | 1129 | 352 | 452 | 552 | 752 | 952 | 1152 | 380 | 483 | 586 | 792 | 998 | 1024 | |||||

| L | CD | 391 |

616 | 688 | 760 | 758 | 856 | 955 | 1510 | 1346 | 1542 | 820 | 920 | 1020 | 1220 | 1420 | 1620 | 915 | 1018 | 1121 | 1327 | 1533 | 1738 | |||

| MD | 638 | 710 | 782 | 780 | 878 | 976 | 1172 | 1368 | 1542 | 820 | 920 | 1020 | 1220 | 1420 | 1620 | 915 | 1018 | 1121 | 1327 | 1533 | 1738 | |||||

m |

104 |

318 | 390 | 462 | 401 | 499 | 597 | 793 | 989 | 1185 | 418 | 518 | 618 | 818 | 1018 | 1218 | 448 | 551 | 664 | 860 | 1066 | 1272 | ||||

n |

130 |

190 |

196 |

240 |

264 |

|||||||||||||||||||||

h |

145 |

152.5 |

190 |

211.5 |

||||||||||||||||||||||

ɸ |

17 |

17 |

20 |

25 |

25 |

|||||||||||||||||||||

B |

279-315 |

279-884 |

279-884 |

279-930 |

279-930 |

|||||||||||||||||||||

F |

355-426 |

354/492 |

400/562 |

438/642 |

||||||||||||||||||||||

Address : No.001,Jingfang Road, Economic & Development Zone, Xinxiang City,Henan Province.China.

Address : No.001,Jingfang Road, Economic & Development Zone, Xinxiang City,Henan Province.China.

Mob :

0086-15137376132

Mob :

0086-15137376132

Tel :

0086-0373-5128206

Tel :

0086-0373-5128206

E-mail :

sales@aidecrane.com

E-mail :

sales@aidecrane.com

Copyright © 2009-2023 All Rights Reserved.

sitemap