Overhead Bridge Cranes

Lifting capacity : 3-250 (ton)

lifting height : 6 9 12 18 24 30 (m)

travelling speed : 20 30 (m/min)

working system : A3-A5

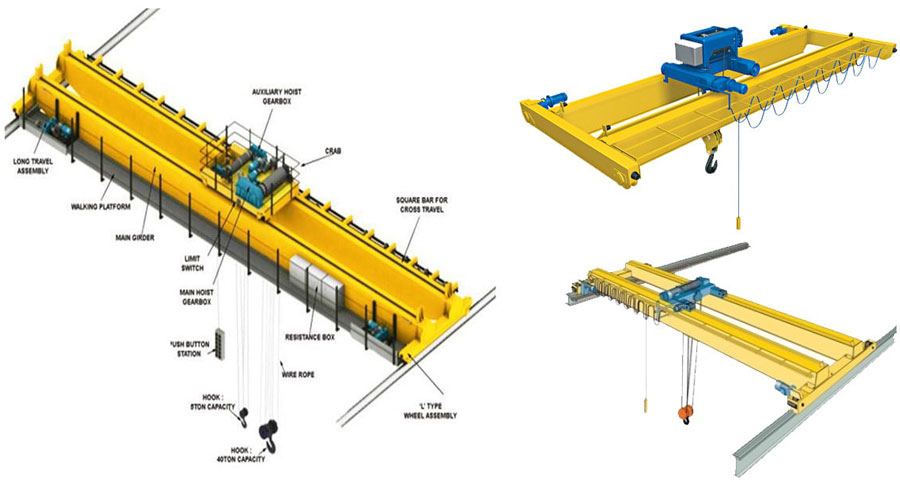

Electric double-girder bridge crane with hook is the widely used hoisting machinery currently. It is mainly comprised of box shape bridge, crane crab, trolley travelling mechanism and electric control system. The load handling device is the hook.

On the girder laid rails for crane crab to transversely move. The girder is weld with the box-shaped end girder. At the middle of the end girder are joints which are fastened with bolts for fragmented transportation of bridges. The platform is used to place trolley travelling mechanism, electric equipment and used for repair.

It has three operation modes: ground handle, wireless remote control and cab. There are two kinds of cab: open cab and closed cab, where there are adjustable seat, insulating mat on the floor, toughened glass for the window, fire extinguisher, electric fan and auxiliary equipment such as air conditioner and alarm which can be furnished as required by users.

Double girder overhead crane can be furnished with load handling devices such as motor grab, electromagnetic chuck to meet the requirements of hoisting varied types of materials.

Overhead crane, of a classification group of A3~A7, has a commonly used lifting load of 3-100 ton, so that it is suitable to work in factories,warehouses and freight yards where the ambient temperature is-10°℃~40°℃ and the relative humidity is not more than 85%. It is prohibited to work in the environment with inflammable, explosive and corrosive gas.

Here you can see the detailed structure of double girder overhead crane. We have QD type and European type bridge crane for clients to choose. This type of overhead crane could greatly improve the working efficiency.

Product Features

The steel structure of double beam bridge crane has reasonable design and optimal structure that meet the requirements of rigidity, strength and stability. The design of steel structure takes into account the convenience and possibilities of manufacturing, transportation, installation, inspection and maintenance.

Be means of optimizing design method such as finite element analysis, the weight of crane metal structure can be minimized.

The compact structure and small wheel pressure can reduce the investment in the early stage of the project, such as the construction of steel structure workshop. At the same time, the expenses on lighting and heating can be reduced.

The uses of quality and high-performance components can help reduce repairing and maintenance work, and also the total energy consumption will be decreased.

Customized configurations are available for your special requirements.

Product parameters

| Mechanism | Item | Unit | Result | ||

| Item | |||||

| Lifting capacity | ton | 3-250ton | |||

| Working grade | A3-A5 | ||||

| Span | m | 7.5-22.5m | |||

| Working environment temperature | °C | -25~40 | |||

| Travelling mechanism | working speed | m/min | 20-75 | ||

| motor | type | YZR160M2 | |||

| power | kw | 2*0.8 | 2*1.5 | ||

| rotational speed | m/min | 1380 | |||

| Lifting mechanism | lifting speed | m/min | 8/0.8(7/0.7) 3.5(3.5/0.35) 8(7) | ||

| lifting height | H(m) | 6 9 12 18 24 30 | |||

| travelling speed | m/min | 20 30 | |||

| working system | A3-A5 | ||||

| power source | 380V 3PH 50HZ | ||||

Address : No.001,Jingfang Road, Economic & Development Zone, Xinxiang City,Henan Province.China.

Address : No.001,Jingfang Road, Economic & Development Zone, Xinxiang City,Henan Province.China.

Mob :

0086-15137376132

Mob :

0086-15137376132

Tel :

0086-0373-5128206

Tel :

0086-0373-5128206

E-mail :

sales@aidecrane.com

E-mail :

sales@aidecrane.com

Copyright © 2009-2023 All Rights Reserved.

sitemap